- 3D Laser scanning and Modeling Services KSA

- 3D Laser scanning and Modeling of plant KSA

- 3D Laser Scanning Services for Oil Refinery KSA

- Piping as built survey KSA

- 3D Laser scanning and Modeling Services Saudi Arabia

- 3D Laser scanning and Modeling of plant Saudi Arabia

- 3D Laser Scanning Services for Oil Refinery Saudi Arabia

- Piping as built survey Saudi Arabia

- 3D Laser scanning and Modeling Services Bahrain

- 3D Laser scanning and Modeling of plant Bahrain

- 3D Laser Scanning Services for Oil Refinery Bahrain

- Piping as built survey Bahrain

BIM MODELING SERVICE IN SAUDI ARABIA

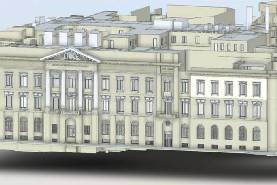

EIWAA LiDAR Scanning Services provides Building Scanning Survey services by 3D laser Scanning, 3D Modeling, Revit Architectural Modeling and BIM Modeling Services etc. To obtain accurate measurements of dimensions and data for Building Information Modeling and Revit Modeling, EIWAA Engineering Survey provides LiDAR Scanning Services and 3D Laser Scanning Services with modern 3D Rendering approach. A particularly accurate method of recording an existing building’s as-built state is to use LiDAR scanning services combined with Revit modeling services. Our skilled team of Revit architectural Modeling Services can swiftly develop REVIT MEP Model structures by using the scan-to-BIM Service.

We can use the Revit Architecture BIM software using building information modeling service after generating the 3D CAD model. Provide your desired degree of information to our 3DLaser scanning service and 3D building information modeling service teams, and they will execute our Revit Architecture 3D Modeling Service. In addition to point clouds, our scanners use on-board HDR color cameras to produce 360-degree panoramic images for BIM engineering and detailing. We are using 3D Scanner, Total station Survey and Topographical services for laser measurement services for better result for building scanning and architectural engineering services.

REVIT MODELING IN SAUDI ARABIA

An extremely precise way to record an existing building’s as-built conditions is by 3D laser scanning or LiDAR Scanning service. We can produce an as-built model with any level of detail you require by using these precise dimensions. Our skilled 3D modeling team swiftly produces high-quality, 3D models using a process known as “scan-to-BIM service”. All the layout of radiators, convectors, ventilating equipment, standpipes, etc. which are to be preserved during the scanning and as a part of REVIT MEP structures. REVIT MEP services, Capable to coordinate and communicate design in a single model prior to the MEP Constructions.

ELEVATION, SECTION AND 2D FLOOR PLAN :

Techniques to produce 2D drawings in a 3D laser scanning project are Exporting BIM model and Create point cloud from 3D scan, We can use BIM software like Revit Architecture to produce standard drawings after developing the 3D CAD model. Through the exact building information/BIM Modeling, data helps to save time. By giving as-built documentation of the areas being developed, it helps in the planning of construction projects.

COLOR POINT CLOUD DATA:

To create an accurate model of a building, point cloud scanning collects millions of data points. By CAD design software, you can use that point cloud data on its own for your projects. With the help of our 3D laser scanning services, we can produce highly accurate data from laser-scanned structures, architectural elements, and complex site topography

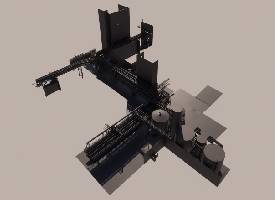

POWER PLANT 3D SCANNING

Power plant 3D scanning services in saudi arabia necessitate the use of high-speed 3D Scanner with a long range and high level of accuracy. Engineers working on power plants can benefit greatly from 3D laser scanning technologies. Engineers may create intricate retrofits and upgrades that fit perfectly when installed by using a digital 3D scan for as-built information, preventing expensive and unavoidable technical mistakes.

3D IMAGING SERVICES IN SAUDI ARABIA

Mode of operation of power plant 3D Scanning or LiDAR Scanning services is the data capturing in 360 degree sweep of all nearby piping, plant equipment’s, storage tanks in a single scan. By merging and modeling of scanned data sections of plant create 3D Imaging. Scan intervals are accurate to ¼” from a distance of 100 meter or more; resulting highly dense accurate as built data. 3D Scan data extract to CAD Model, Panoramic Image and Ortho Image.

BIM MODELING IN SAUDI ARABIA

This is the process of converting point clouds into Autodesk Revit Architecture model by BIM Modeling Services in Saudi Arabia. In comparison to conventional methods, the process converts 3D laser scanning data into BIM Model. as precise and faster. It is the only viable option for architects and engineers to record an as-built model and drawings as a part of BIM Engineering. An accurate digital representation of the existing building is created from the scanned data. A 3D Modeler may transform the scan data into an as-built model.

SCAN TO BIM IN SAUDI ARABIA

Almost any construction project can benefit by using building information modeling or Scan to BIM Services in saudi arabia. Scan to BIM Services are used where as-built models required for a hotel renovation, redesigning a hospital floor, or demolishing an office building etc. Other applications like organizing escape routes and figuring out how much room is needed for ventilation and fire systems. Assessing the status of building projects is significantly simpler with Building Information Modeling or by BIM Engineering service. A 3D laser scanner is first used to gather data. The point cloud captures the current state of the building project. Using programs like Autodesk Navisworks, makes it possible to compare the design model with the scan data. All of this information is tracked in Building information model, confirming that the building complies.

3D CAD Modeling & BIM Model

BUILDING ARCHITECTURAL MODELING IN SAUDI ARABIA

Our scanning and modeling teams will set to work as soon as you let them know how much detail you require. You will receive a very accurate 3D Model of the as built condition that you may use to create your project design and engineering models, whether it is LOD200, LOD300, or LOD400.

ASBUILT 3D MODELING IN SAUDI ARABIA

We can scan a significant portion of your Plant in a single day by quick scanning. With great productivity, our skilled team of CAD modelers extracts the datas by scan the piping, conduit, structure, valves, pumps, storage tank, and everything else you require. Any level of detail (LOD) you select for this modeling can achieve and giving you Asbuilt 3D model.

PIPING ASBUILT 3D MODELING SAUDI ARABIA

Your As-Built drawings can be updated or totally recreated by using 3D scanning if it is outdated. A variety of file formats are available for CAD models produced from 3D Scans. You decide what components and how much detail you want to view in the CAD model. Depending on the objectives of the project, CAD modeling might be done for the complete facility or simply a specific sector by using Autodesk TrueView.

BIM 360 IN SAUDI ARABIA

Our scanners use on-board HDR color cameras to take 360-degree panoramic images for BIM Engineering or BIM 360 detailing. Softwares of Autodesk Recap or Leica Truview to view these pictures of BIM 360. When you require high resolution images from every scan site, the panoramic photographs are fulfilling your project requirements.

FLOOR PLANS AND ELEVATIONS

From 3D scan data, floor plans and elevation drawings can be produced by 3D Building scanning services. In order to create floor plans for space planning or achieving building permits, our customers have used 3D scanning and get the basic line drawings.