NON DESTRUCTIVE TESTING & NDE

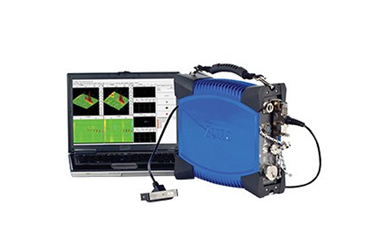

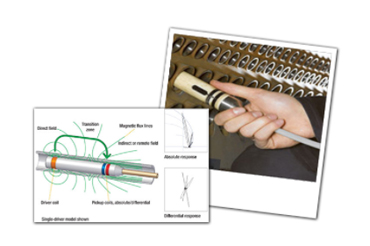

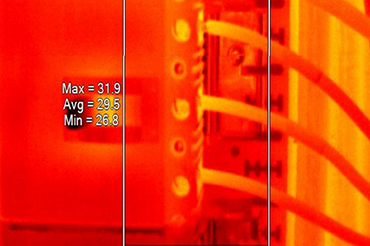

EIWAA Oil and Gas Services provides various advanced Non destructive inspection services for oil gas contractors, Storage tank Terminals, Piping Contractors, Pipe line contractors, Ship building contractors etc. Advanced NDT Inspection services of Magnetic Flux Leakage(MFL Inspection), ACFM Inspection Services, Chiller tube inspection Services etc. are applicable for Storage tank Inspection, Boilers, Heat Exchangers and Power plants. EIWAA Oil and Gas Services is one of the major predictive maintenance inspection services by providing vibration analysis, thermal imaging and thermographic survey and noise survey services in Saudi Arabia. Eddy Current tube Inspection Services in remote field technique are used for chiller tube inspection and Heat Exchanger tube corrosion mapping . In Processing and Power Plant, Vibration analysis and Vibration Monitoring services are used for preventive maintenance surveys. Thermography Inspection for Electrical Connections and Electrical Panels in Hotels and Restaurants is a part of predictive maintenance survey services. Electromagnetic Wire rope testing is a proven NDT Testing method to interpret the defects of kinking, Loss of Metal, abrasion, corrosion, broken strands etc. EMAG or Wire rope NDT Inspection or NDT Service is used in many areas of Passenger ropeway inspection, ship lift inspection, zip line inspection, main hoist inspection, crane wire rope inspection etc.. Thermography Inspection Services in Saudi Arabia is used to measure building leakage identification by using the temperature difference interpretation and evaluation. Energy auditors can evaluate the efficiency of the insulation used in a building’s construction using infrared scanning. Thermographic Inspection by thermal imaging scans of roofs can frequently find roof leaks because wet insulation conducts heat more quickly than dry insulation. Videoscope and Borescope Inspection of NDT Inspection Service are used for condition monitoring and inside condition of pipes to ensure remaining life assessment of piping and pipeline system as a part of In service API Inspection of piping.