BRAZING TEST IN SAUDI ARABIA

EIWAA Oil and Gas Services offers Manual Torch Brazing Training, Third Party Brazing Test, Third Party Brazing Test & Brazing Certification Services in Saudi Arabia. We qualify brazing procedures so that companies can meet industry standards and accomplish their objectives. Our team of experts come to the customer’s location to go over, understand, and suggest the necessary Brazing procedures in order to be qualified and supported, from test coupon preparation to actual testing and certification. We offer brazing procedures in accordance with BS EN 13134:2000 (Brazing Procedure Approval) and ASME Sec IX (Boiler and Pressure Vessel Code).

We provide third-party brazer training packages, witness and certify BPS/BPQR qualification tests, witness and certify operator qualification tests, perform mechanical testing (peel, fracture, and section tests), perform macro examinations, certify procedures, prepare procedures, and apply procedures. The international welding codes ASME SEC IX and BS EN must be followed in all mechanical testing. The brazing certification service includes electrode information, mechanical test report information, F and A numbers, base material information, and brazer certification.

BRAZING CERTIFICATION SERVICES IN SAUDI ARABIA

EIWAA, one of the best brazing training centres in Saudi Arabia provides a variety of brazing certification services in addition to brazing courses. We provide a variety of third-party brazing certification services, such as brazing procedure qualification, procedure qualification approval, NDT testing, brazing qualification testing, and brazer certification. We are an AWS-accredited brazing and welding training institute in the Saudi Arabia. In compliance with ASME SEC IX and BS EN, we offer brazing operator training and brazing instruction as a Third Party brazing testing service provider in Saudi Arabia. Our open sessions assist HVAC companies in Saudi Arabia with the ISO/IEC 17020 brazer certification process. The UAE-based third-party brazer testing company we work with certifies brazing operators and brazers at different levels. Numerous third-party welder testing companies and Brazing Qualification certification services, such as Copper and Manual Torch brazing certification, are available in Saudi Arabia.

Your brazing operator’s brazing performance will be observed on site by our skilled brazing engineer. The brazing operator must work in both vertical and horizontal positions. A coupling and copper tube with the necessary thickness make up the brazing test coupon. A test coupon that meets the visual qualification requirements will be collected from the site and submitted to laboratory testing for mechanical testing, including peel, section, and tensile tests. Issue a brazing certificate and brazer ID card based on the operator’s mechanical test coupon results.

BRAZING PROCEDURE QUALIFICATION

Brazing Procedure Qualification Record (BPQR) – Brazing Procedure Qualification record is a documented record of a brazing procedure qualification including all mechanical test reports, base material, consumable and essential variables of manual torch brazing.

Brazing Procedure Specification (BPS) – Brazing Procedure Specification is a document that specifies the parameters, consumables, preparation, run position, run sequence, and other details relevant to the brazing procedure.

Brazing control involves the following:

Brazing procedure development and specifications

Brazing procedure qualifications

Brazing procedure qualification records

Brazer Certification

Brazing procedure specification

Brazer and Brazing operator qualification.

Brazing Procedure Qualification and Specification:

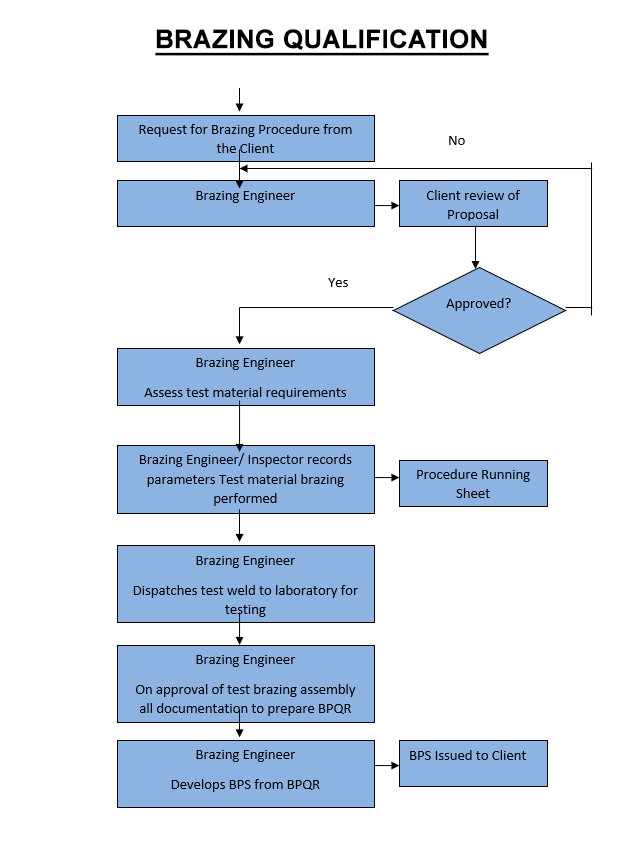

When Brazing procedures are required by a client, Qualified Inspection Engineer develops a preliminary Brazing Procedure Specification (pBPS) to suit the client requirements.

Details of the preliminary brazing procedure are prepared and submitted to the client for approval to conduct the brazing qualification test.

Brazing Procedure Qualifications (BPQ)

The Brazing Engineer or brazing Inspector ensures that each new pBPS is qualified in accordance with the Client’s requirements and relevant brazing standards and codes. The Brazing Inspector ensures suitably skilled personnel and adequate supplies of brazing consumables and test pieces are available for testing.

The Brazing Inspector records all necessary brazing parameters on a Procedure Running Sheet during qualification. After visual acceptance of brazing test coupon, the Brazing Inspector identifies the brazing test piece using a marker pen.

Brazing Engineer raises mechanical testing requests for visually accepted brazing test coupon .Mechanical Test shall be Peel test, section test and macro examination as per ASME SEC IX and BS EN.

Brazing Procedure Qualification Record (BPQR)

Following successful testing, the Brazing Engineer compiles a Procedure Qualification Record (BPQR) which consists of procedure running sheet, mechanical test result and actual variables of manual torch brazing

Brazing Procedure Specification

The Brazing Engineer assigns a unique number to the BPS in consultation with the client. The brazing parameters detailed on the BPS are those that will be worked to in the field. BPS and BPQR are forwarded to the Client for approval.

Brazer and Brazing Operator Qualifications

- Brazing Operators are qualified in accordance with the requirements of the Client and relevant standards or codes like AWS, ASME SEC IX, BS EN, ISO, and API Standards. The test is carried out as per an approved brazing procedure.

- Brazer qualification test details are recorded by the Brazing Inspector during the Brazer Performance Qualifications these are signed stamped and approved by the Brazing Engineer.

DELIVERABLES OF BRAZING PROCEDURE QUALIFICATION TEST:

Deliverables of Procedure Qualification Test are;

Brazing Procedure (BPS)

Procedure Qualification Records (BPQR)

Mechanical Test report

Brazing Certificate of Successful Brazing operators

ID Cards etc.