- 3D Laser Scanning Services KSA

- Marine 3D laser scanning and Modeling survey KSA

- scrubber unit(EGCS) installation KSA

- Ballast water treatment System(BWTS) installation KSA

- 3D Laser Scanning Services Saudi Arabia

- Marine 3D laser scanning and Modeling survey Saudi Arabia

- scrubber unit(EGCS) installation Saudi Arabia

- Ballast water treatment System(BWTS) installation Saudi Arabia

3D LASER SCANNING AND MODELING

3D Laser scanning and modeling of ships, vessels, and offshore rigs is a sophisticated and valuable service in the maritime and offshore industries. These technologies can provide detailed digital representations of the physical structures, allowing for accurate measurements, analysis, and planning for maintenance, modifications, or new construction projects.3D scanning and modeling services such as laser scanning, photogrammetry, and computer-aided design (CAD) modeling shall be provided by EIWAA Marine Services at Major ports of Saudi Arabia. Our LiDAR scanning, 3D mapping, and 3D modeling services can offer significant benefits for marine ports and offshore facilities. These technologies can provide accurate and detailed information about the topography, infrastructure, and assets in marine environments and Major Ports of Saudi Arabia. By using LiDAR scanning services, marine ports and offshore facilities can create highly accurate 3D maps of their surroundings, including underwater features. This can be invaluable for activities such as dredging, construction, and environmental monitoring.

3D MAPPING AND ASBUILT MODELING

The use of 3D laser scanning technology has revolutionized the way that as-built modeling of ships and vessels is carried out in the marine industry. By utilizing this advanced technology, marine engineers are able to quickly and accurately capture the existing conditions of a ship or vessel in 3D, which can then be used to create detailed as-built models for planning and design purposes.3D laser scanning services allows for rapid data collection in even the most complex and hard-to-reach areas of a ship or vessel, resulting in a comprehensive and highly accurate representation of the structure. By using 3D laser scanning and as-built modeling, marine engineers are able to save time and reduce costs compared to traditional methods of manual measurement and drawing preparation. Additionally, the level of accuracy and detail provided by 3D laser scanning ensures that the resulting models are highly accurate and reliable for use in a variety of marine engineering applications. When it comes to vessels and ships, 3D mapping and as-built modeling technologies play a crucial role in the marine industry. These advanced tools are used to capture the existing conditions of ships and vessels, create detailed as-built models, and assist in various marine engineering applications.

HULL AIR LUBRICATION SYSTEM

3D laser scanning and modeling are increasingly being used in the marine industry, particularly in the design and optimization of hull air lubrication systems. Hull air lubrication systems are innovative technologies that reduce the drag on a ship’s hull by introducing a layer of air bubbles underneath the vessel, thereby decreasing fuel consumption and emissions. Our first step in implementing a hull air lubrication system is to scan the ship’s hull using 3D laser scanning technology. This process captures detailed 3D data of the hull structure, including its shape, dimensions, and surface condition. The data collected through 3D laser scanning is then processed to create an accurate 3D model of the ship’s hull. Using computational fluid dynamics (CFD) simulations, engineers can analyze the airflow dynamics around the hull and assess the performance of the air lubrication system. The 3D model of the hull provides a realistic representation of the ship’s geometry, enabling accurate simulations and predictions.

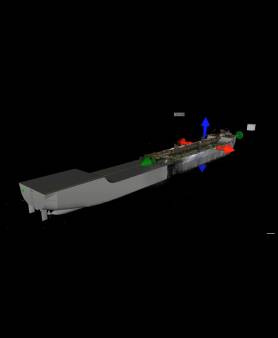

SHIP HULL AND KEEL LASER SCANNING AND MODELING

3D laser scanning and modeling are invaluable tools in the marine industry for capturing accurate data of ship hulls and keels. The hull and keel are critical components of a ship’s structure that affect its performance, stability, and hydrodynamics. Hull and Keel laser scanning services are used to capture precise data with detailed measurements and dimensions of the hull surface, keel geometry, and other structural elements.3D model accurately represents the geometry, shape, and condition of these components, allowing for in-depth analysis and visualization. Hydrodynamic Analysis used to assess the ship’s performance in various operating conditions as per IMO/IACS regulations. Engineers can analyze the flow of water around the hull and keel, study resistance and drag forces, and optimize the design for improved efficiency and it can alternatively using for structural integrity assessment. By visualizing the existing conditions of these components, engineers can identify areas that require maintenance, design modifications, and coordinate repair work more effectively.

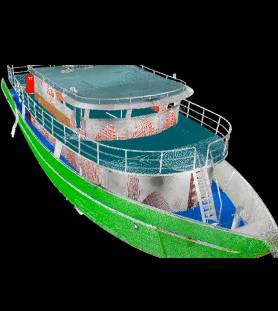

BOAT AND YACHT LASER SCANNING AND RETROFITTING ENG

3D laser scanning and modeling are increasingly being used in the marine industry for retrofitting engineering and as-built surveys of boats and yachts. Retrofitting involves upgrading or modifying existing vessels to improve performance, enhance safety, or comply with regulations. As-built surveys are conducted to document the current condition and dimensions of a vessel for various purposes. The first step in retrofitting engineering or conducting an as-built survey is to perform a 3D laser scan of the boat or yacht. The laser scanner captures detailed measurements and data of the vessel’s structure, components, and interior spaces with high precision. The data collected from the laser scan is processed to create a detailed 3D model of the boat or yacht. This model accurately represents the vessel’s geometry, layout, and design, providing a digital twin of the actual vessel for analysis and visualization purposes. With the 3D model of the boat or yacht in hand, engineers can plan and design retrofitting projects more effectively.