RETROFITTING ENGINEERING

EIWAA Marine Services provides 3D Mapping, Laser Measurement Services, 3D imaging services,3D Modeling and Marine Laser Scanning Services in Saudi Arabia. Our marine 3D Scanning and Modeling Service using offshore Laser scanning to capture and optimize “As-Built” data and creating asbuilt Models. Our offshore 3D Laser scanning service relevant to the entire cycle of shipbuilding and maintenance projects shall be performed by Naval Architects, Marine Engineers and Designers by using 3D Laser scanner.

OFFSHORE CONVERSION ENGINEERING:

Engineering for offshore conversion and design starts with feasibility, layout, stability, structural foundation, machinery systems, piping, electrical, etc. We are working on a variety of conversion projects under Major Classification Societies by creating designs, calculations, and documentation for vessels, barges and dredges. For a wide range of vessels undergoing retrofits and conversions, we can offer structural design and analysis, stability studies and statutory plans, etc.

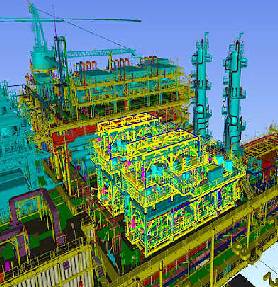

3D SCANNING OF OFFSHORE PIPING

For offshore piping projects, we specialize in designing precise piping and pipeline systems using our in-house dimensional control and laser scanning team of 3D Imaging and 3D Marine Surveyors. The methods we use to guarantee that new spools fit correctly and without clashes have been refined. Engineers can decide how to modify the existing piping system to accommodate the equipment installation by using an accurate model of the system currently in place.

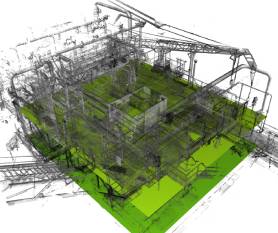

ONBOARD 3D IMAGING MEASUREMENT

Precise and effective model of the pipe systems in an engine room can be made using a 3D Digital Survey Services of the piping in the engine room. Additionally, these records can be used for are Ship’s Inspection and Repair. Onboard Scanned data Used as a reference for Retrofit and Installations. The ship’s engineer requires precise measurements of the engine room in case a ship needs maintenance in port or has a problem at sea.

PHOTOGRAMMETRY AT OFFSHORE PLATFORM

3D Scanning of high-definition, 360-degree photographs of the offshore asset and visual walkthrough. Enhances critical engineering data for offshore installations and commissioning. Advantages of Panoramic View and Photogrammetry are Full-colour, high-definition 3D image capture in its complete form.

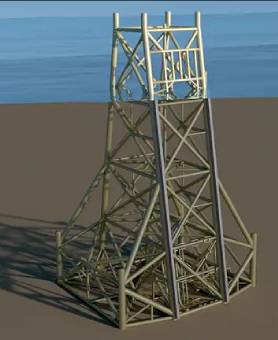

ANALYSIS OF FIXED AND FLOATING OFFSHORE UNITS

For our clients in various industries like as Oil and Gas, Marine, Renewable energy etc., We have expertise in designing a variety of fixed, floating, or mobile offshore units. For emerging technologies and designs, our specialized services include conceptual studies, FEED design, and detail engineering.

ASBUILT SURVEY OF OFFSHORE INSTALLATION

We are expertise to perform as-built surveys for ships and offshore installations (oil rigs) in reverse engineering. We can either create intelligent models that are compatible with AVEVA PDMS, AutoCAD Plant, or Open Plant, or we can convert the point cloud into simple 3D CAD models. Similar to offshore industrial sites, we may assist our customer during the design phase by completing conflict analyses and even making recommendations for the best routes for pipelines and locations for equipment.