How to perform Brazing Operator Qualification Test and Brazing Procedure Qualification…?

Brazing control involves the following:

- Brazing procedure development and specifications

- Brazing procedure qualifications

- Brazing procedure qualification records

- Brazing procedure specification

- Braze and Brazing operator qualification.

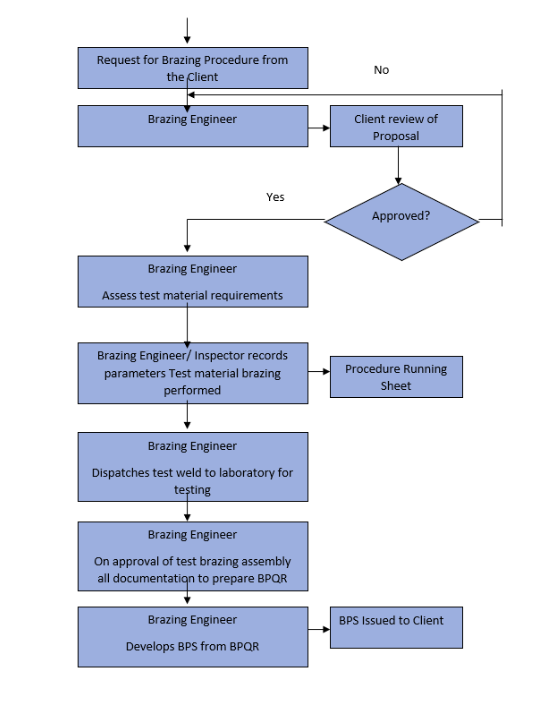

Brazing Procedure Development and Specification:When Brazing procedures are required by a client,The ASME/BS EN Qualified Inspection Engineer: develops a preliminary Brazing Procedure Specification (pBPS) to suit the client requirements.Preliminary Brazing Procedure Specification (pBPS): Details of the preliminary brazing procedure are prepared and submitted to the client for approval to run the test coupon.

Brazing Procedure Qualifications (BPQ):The Brazing Engineer or brazing Inspector ensures that each new Pbps is qualified in accordance with the Client’s requirements and relevant standards and codes.The Brazing Inspector ensures suitably skilled personnel and adequate supplies of brazing consumables and test pieces are available for testing. The Brazing Inspector records all necessary brazing parameters on a Procedure Running Sheet during qualification of the BPQ.Where required by the contract the Client’s representative and/or certifying authority is given adequate notice prior to commencement of any qualification.

After visual acceptance, the Brazing Inspector identifies the test piece by the use of a marker pen with the following:

- BPS number

- Brazer identification – name and unique number

- date

- top of coupon.

The Brazing Inspector raises a material requisition for the testing of the brazing test piece ensuring all the necessary data, eg brazer’s name, number, BPQ number, material type, applicable standards or codes being worked to, are identified.Upon completion, all testing records are reviewed by the Brazing Engineer to ensure compliance.

Brazing Procedure Qualification Record (BPQR)

Following successful testing, the Brazing Engineer compiles a Procedure Qualification Record (BPQR) which consists of:

- BPQR

- Procedure Running Sheet

- Test results

- Material and consumable certification.

The Brazing Engineer, signs the PQR sheets in the space provided.

Brazing Procedure Specification

- The Brazing Engineer assigns a unique number to the BPS in consultation with the client.

- The brazing parameters are detailed on the BPS are those that will be worked to in the field. BPSs and BPQR are forwarded to the Client for approval.

Brazer and Brazing Operator Qualifications:

Brazers or Brazing Operators are qualified in accordance with the requirements of the Client and relevant standards or codes like AWS,ASME SEC IX,BS EN,ISO and API Standards. The test is carried out as per an approved brazing procedure. The brazing Inspector verifies the brazers’ test piece, upon completion, meets the requirements of the Client and relevant standards or codes. Brazer qualification test details are recorded by the Brazing Inspector on the Brazer Performance Qualifications and these are signed and stamped and approved by the Brazing Engineer or delegate.

DELIVERABLES OF BRAZING PROCEDURE/BRAZER QUALIFICATION TEST:

Deliverables from EIWAA Marine’s following the Brazer Test and Brazing Procedure Qualification Test are;

- Brazing Procedure (BPS)

- Procedure Qualification Records(BPQR)

- Mechanical Test report

- Brazing Certificate of Successful welders

- Brazer ID Cards etc.